Rotary type sifter

RUBERG-Rotary-Type Sifters series RWS are a suitable RUBERG development to extend the possibilities of sifting technology. Characteristics of products and mesh sizes of screen mesh define throughput rates. Four different sizes of mesh cover a wide range of services.

Adequate product quantities are conveyed by an integrated metering screw feeding into the sifting chamber.Therefore special feeding of metering devices are not required. Products are centrifuged by beater ribs onto the sifting cylinder with product passing through the screen mesh. Due to this procedure possible lumps and agglomerates are broken down. Sifted fine product is collected inside the discharge funnel. The shape of the beater ribs direct the coarse material is thrown further inside the sifting cylinder to be discharged at the opposite end.

Design variations:

- Housing made of stainless steel, material 1.4301 or 1.4571, also available mild steel

- Integrated metering screw, optionalls with extended metering channel

- Front supported shaft with seal by purge air

- Balanced rotor shaft with adjustable beater ribs

- Cover of sifting cylinder available with nylon or stainless steel mesh

- Inspection and access door with safety limit switch

- Driven by electric motor and protected v-belt drive

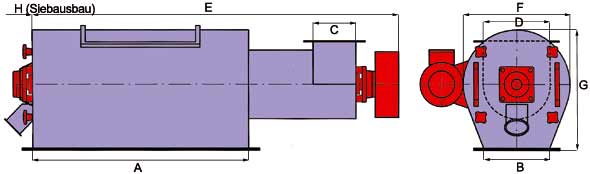

| Type | Size of Sieve in mm in mm | Sifting Area in mm | A in mm | B in mm | C in mm | D in mm | E in mm | F in mm | G in mm | H in mm |

|---|---|---|---|---|---|---|---|---|---|---|

| RWS 1-220 | ø220 x 500 | 0,35 | 500 | 200 | 200 | 400 | 1265 | 400 | 450 | 650 |

| RWS 2-220 | ø220 x 1000 | 0,68 | 1000 | 200 | 200 | 400 | 1765 | 400 | 450 | 1150 |

| RWS 3-320 | ø320 x 1000 | 1 | 1000 | 300 | 250 | 500 | 1765 | 500 | 550 | 1150 |

| RWS 4-320 | ø320 x 1500 | 1,5 | 1500 | 300 | 250 | 500 | 2265 | 500 | 550 | 1650 |