RDF series

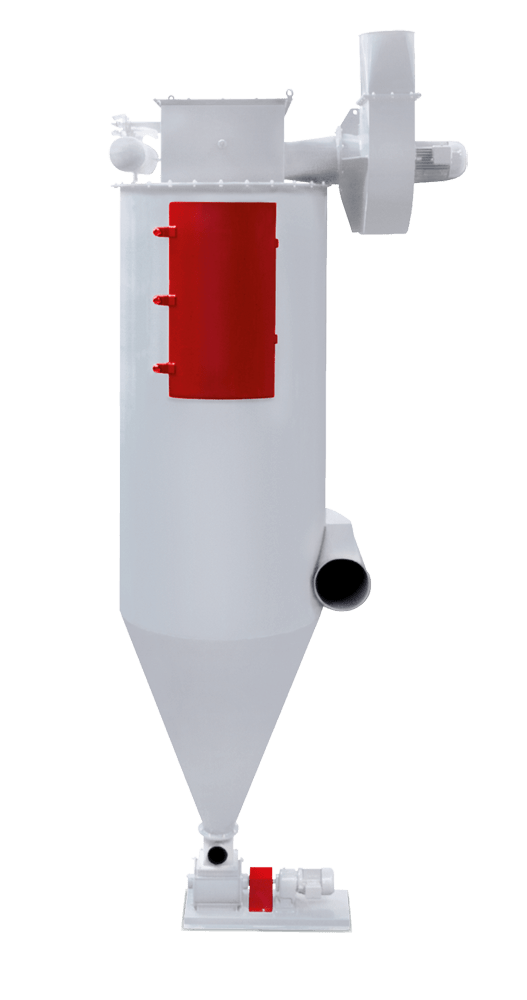

Separation of product during suction or pressure conveying, dedusting and cleaning of dust-laden air or gas mixtures from process and central aspirations: these are some examples of what the RUBERG nozzle filter can do. It can be used powerfully and reliably for these tasks.

This system allows a wide range of applications thanks to the design arrangements of the standard versions. This ensures that the filter elements are protected against wear by appropriate guidance of the raw gases. Residual dust contents of less than 2 mg/m³ at the clean gas outlet allow heated process air to be returned to the system while staying well below the limit values set by German Technical Instructions on Air Quality Control (TA-Luft) and Maximum Allowable Concentration (MAK) standards.

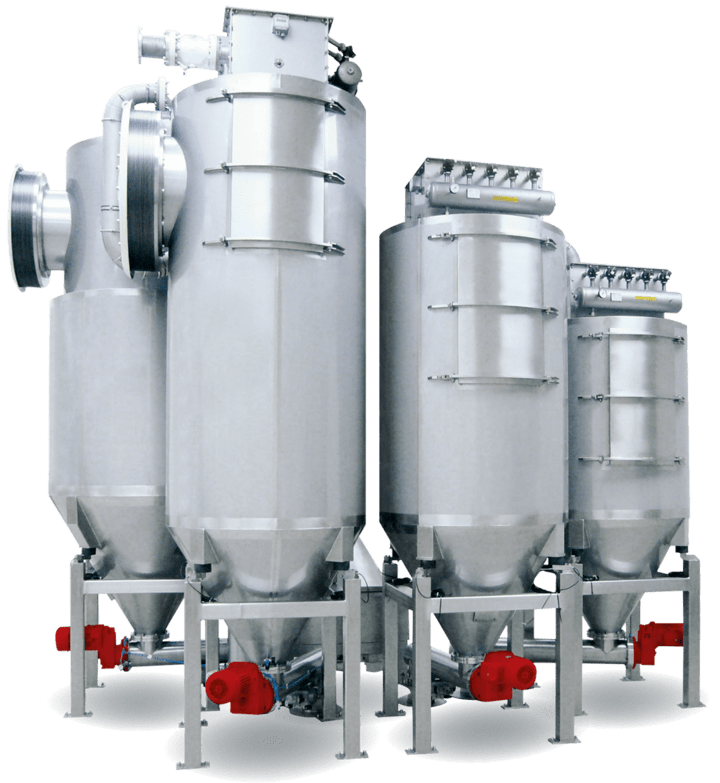

When using explosion-proof valves, controls and accessories, RUBERG nozzle filters can be used in hazardous areas according to ATEX classes. Standard and stainless steels, special and wear-resistant steels with ground, blasted or painted surfaces offer possible applications in the food, chemical, agricultural and animal feed industries as well as other industries not mentioned here.

A variety of sizes with a modular design result in individually adapted filter units for a wide range of applications.

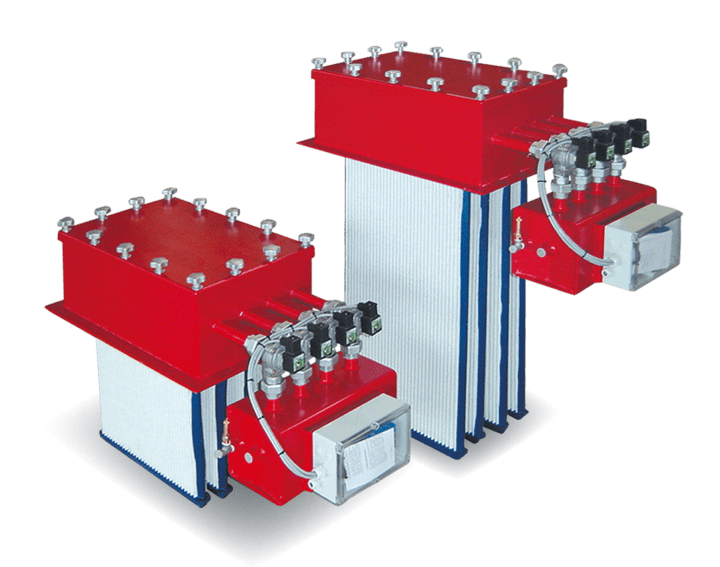

Discharge aids, airlocks, fans, throttles and other accessories complete the RUBERG product range.

Info & downloads

Example tasks:

- Dusting

- Vacuuming

Application areas:

- Cereals

- Coffee & tea

- Oilseeds

Industries & products

Baby food

Baking agents

Building materials

Chemistry

Animal feed

Spices

Plastics

Food

Pharmacy

Ask us!

Would you like a consultation, more information on this machine solution or are you generally looking for a customised overall solution? – Get in touch with us now... Of course, you can also call us directly: Phone number: +49 (0) 5274-98510-0.

We look forward to your inquiry.