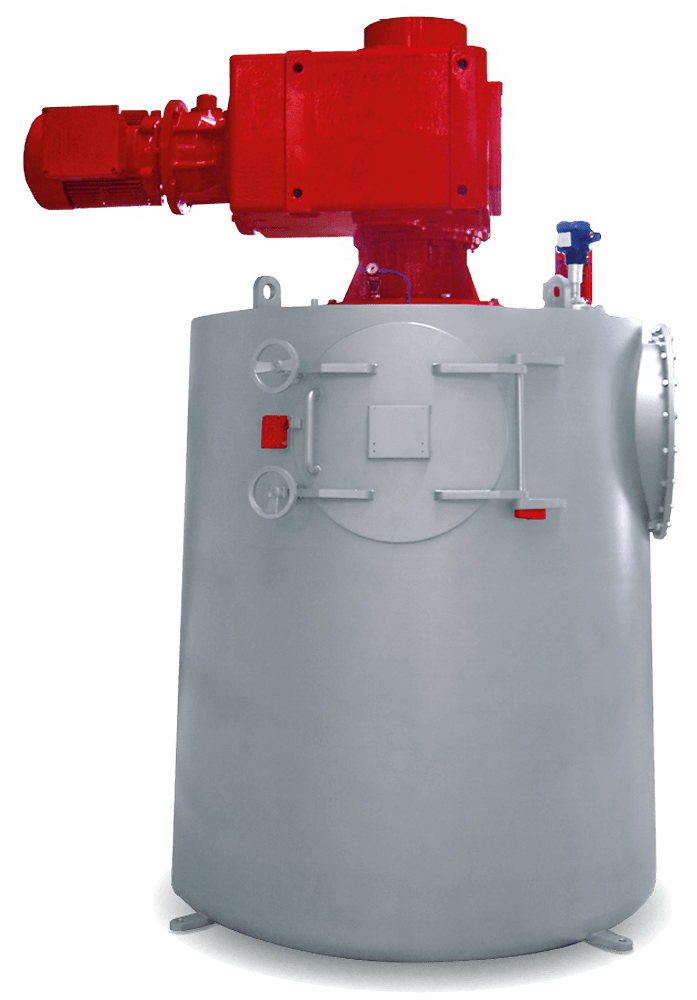

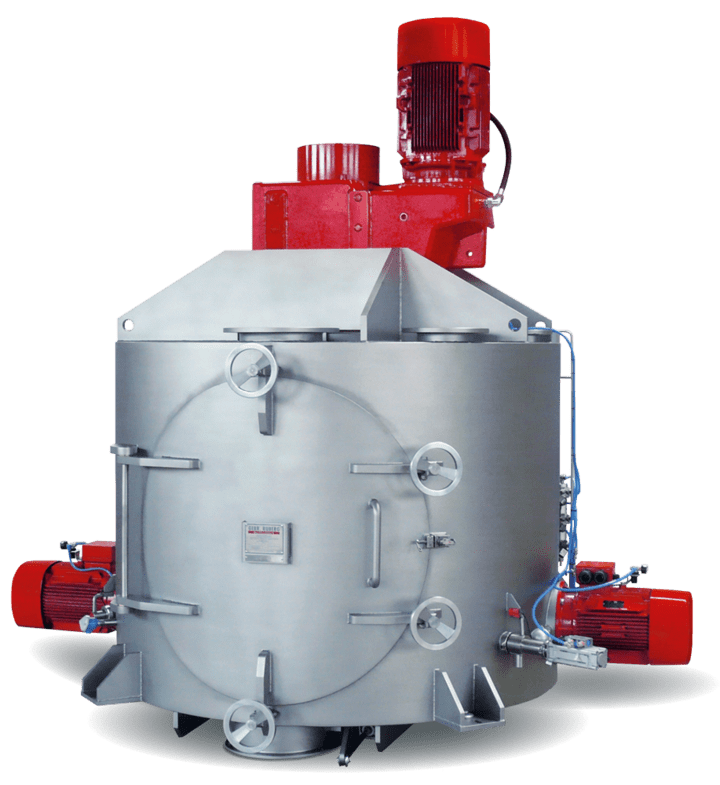

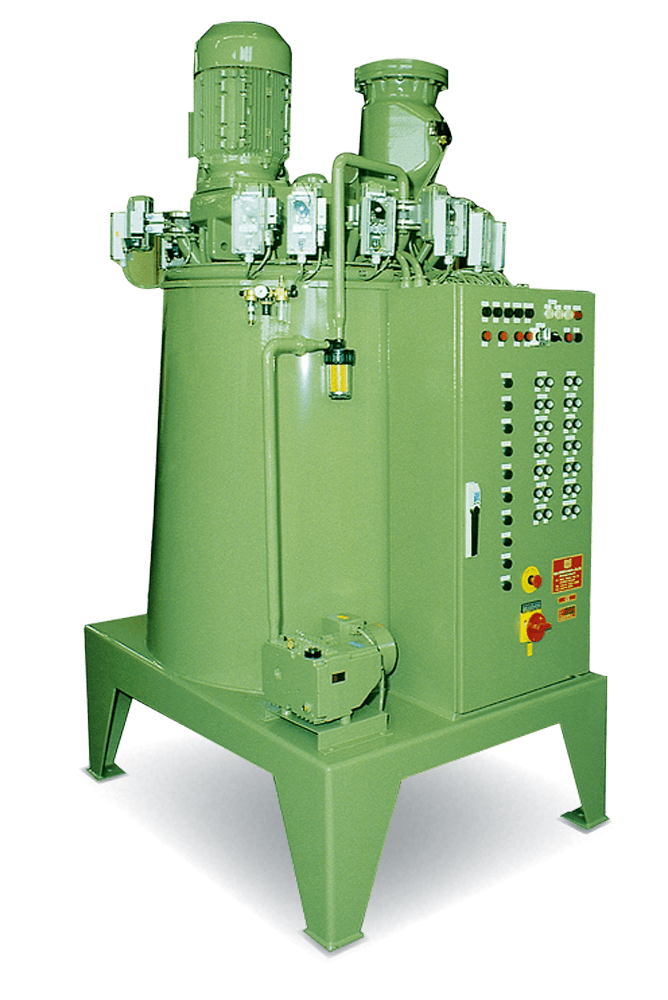

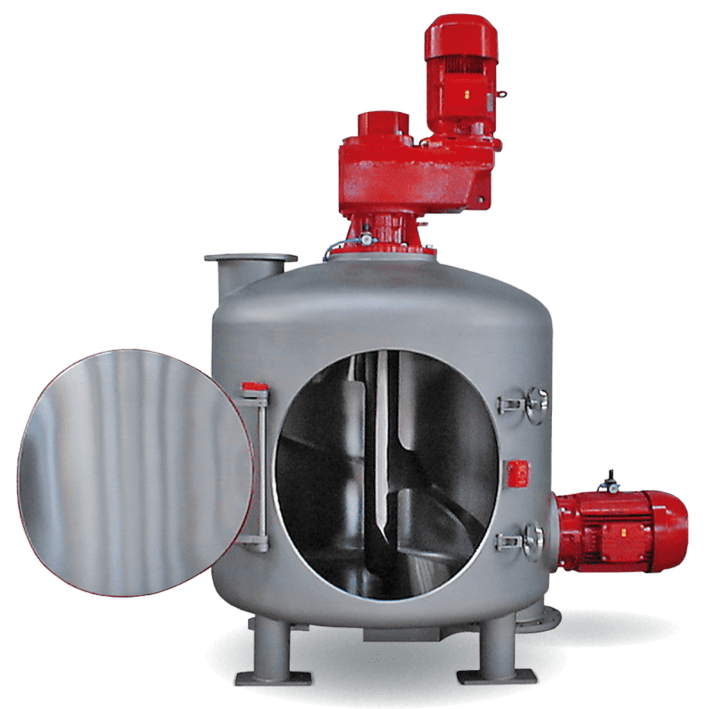

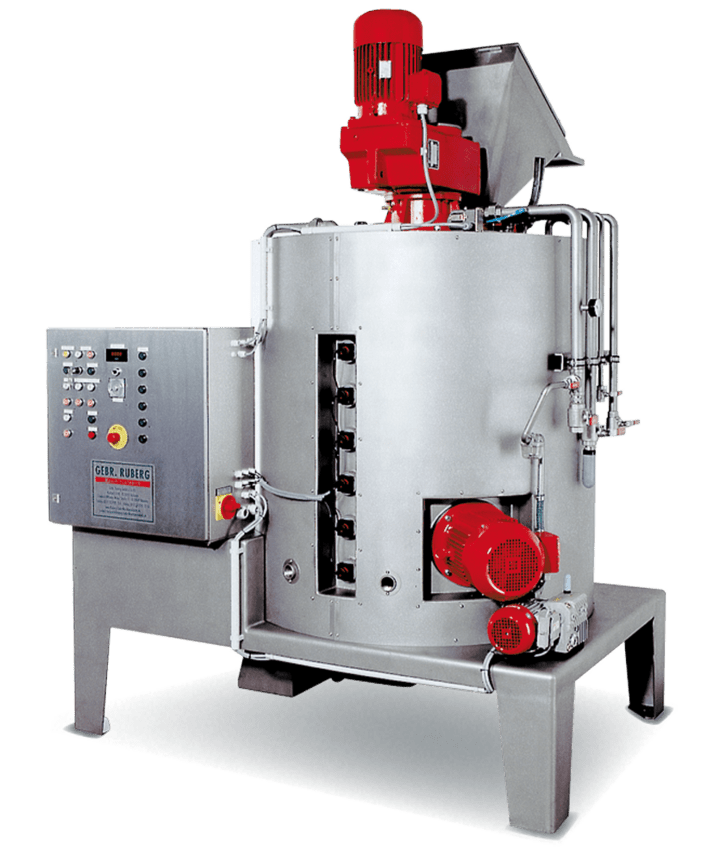

Machine type: CM series

Due to the wide range of raw and finished products and their diverse requirements for materials and processing quality, RUBERG has developed six main types within the CM series over years of innovation, each with different designs. Combined with additional equipment, these units form RUBERG precision batch mixers, optimised for quality and cost-efficiency, handling tasks for powders, granules and low- to high-viscosity liquids.

Tasks such as homogenizing, coating, wetting, crystallizing, degassing, foaming, steaming, fluidizing and drying are just a few examples of the mixing challenges that RUBERG precision batch mixers are built to address. These mixers deliver high performance and flexibility,

handling sensitive products from the pharmaceutical, fine chemical and food industries, as well as bulk goods in chemicals, building materials, plastics and animal feed.

With rapid processing times, they achieve a high degree of mixing precision in as little as 30–180 seconds (as quick as 30 seconds for muesli). The variable speeds, tailored to the mixed material, allow for gentle blending of coarse-grained materials and intensive dispersion of fine powders, paints, coatings, or liquid substances at higher speeds. Available in working volumes from 100 to 25,000 litres, these mixers are constructed from premium stainless or special steels. They ensure the highest mixing precision of 1:100,000, even at variable fill levels starting from just 10% capacity.

Info & downloads

Example tasks:

- Mixing

- Batch mixing

- Deagglomeration

- Inerting

- Homogenizing

- Dispersion

- Drying

- Compacting

- CIP

Application areas:

- Baby food

- Baking agents

- Building materials

- Chemistry

- Animal feed

- Cereals

- Spices

- Coffee & tea

- Plastics

- Food

- Pharmacy

Industries & products

Oilseeds

Ask us!

Would you like a consultation, more information on this machine solution or are you generally looking for a customised overall solution? – Get in touch with us now... Of course, you can also call us directly: Phone number: +49 (0) 5274-98510-0.

We look forward to your inquiry.