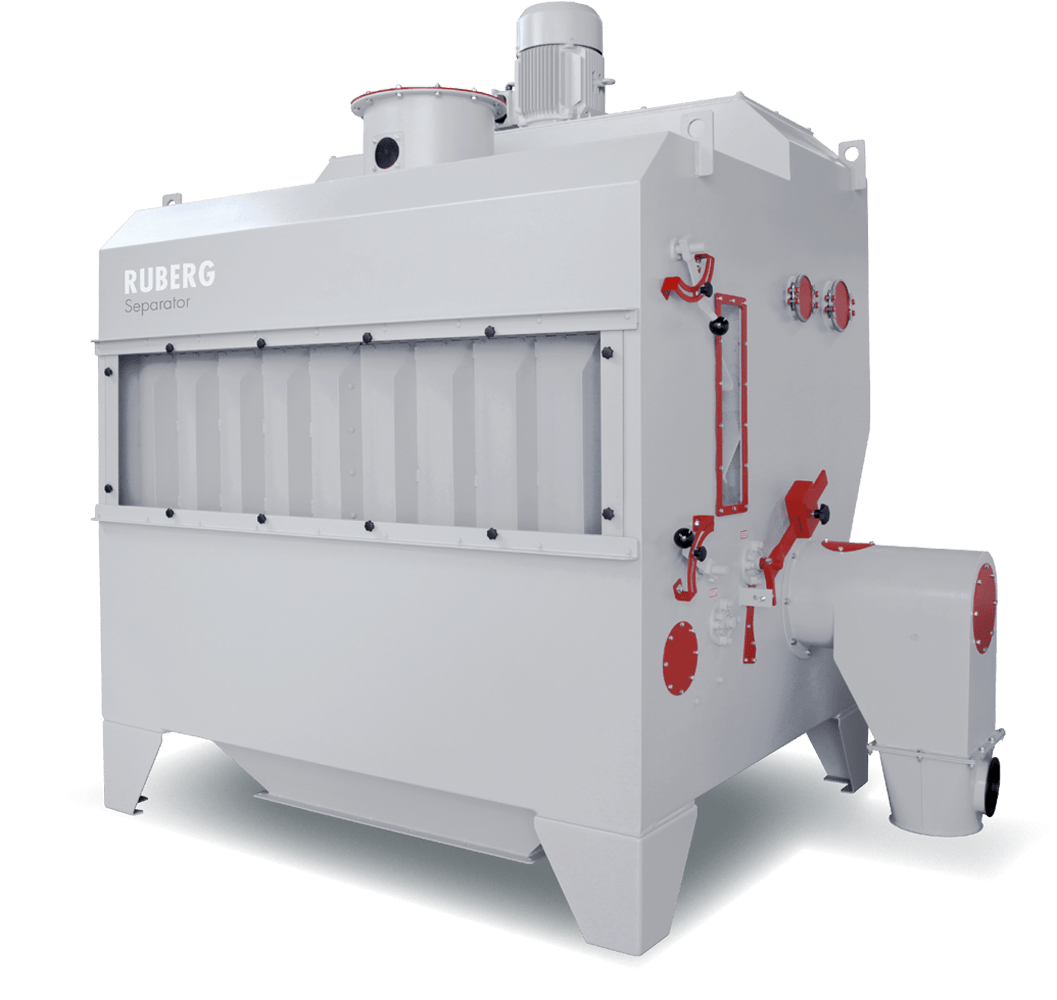

RS series

RUBERG separators are an effective, reliable and easy-to-maintain solution for cleaning cereals, oilseed crops and legumes in recirculation mode.

Different machine widths are provided according to the throughput rate in order to achieve the best possible results. In a sturdy sheet steel construction, the RUBERG separator offers space-saving and user-friendly benefits. Inlets and inlet distributors feed the product to be cleaned into the pre-distributor, where a product curtain is created by the feed flap and feed roller. Dust and light particles are picked up by the rising air stream and carried into the separation chamber. They are then transported out of the side of the machine by a screw conveyor.

Info & downloads

Example tasks:

- Grain cleaning

- Sieving

- Fractionating

- Sorting

Application areas:

- Cereals

- Coffee & tea

- Oilseeds

Industries & products

Baby food

Baking agents

Building materials

Chemistry

Animal feed

Spices

Plastics

Food

Pharmacy

Ask us!

Would you like a consultation, more information on this machine solution or are you generally looking for a customised overall solution? – Get in touch with us now... Of course, you can also call us directly: Phone number: +49 (0) 5274-98510-0.

We look forward to your inquiry.