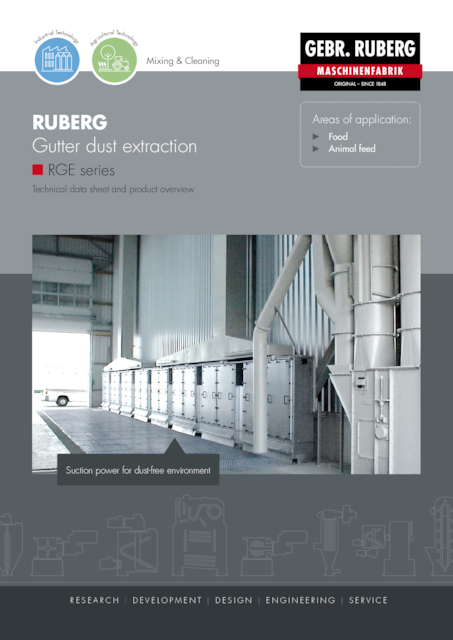

RGE series

RUBERG's powerful suction solution for low emissions when delivering dust-intensive bulk materials: RUBERG gutter dust extraction plants are available as vibrating hose extraction wall, nozzle hose extraction wall or as extraction wall with decentralised filter system.

RUBERG lamella dumping gutters: Input gutters with high frequency can be equipped or retrofitted with an additional lamella system. This sealing system closes off the grate system at the top in such a way that no dust-air mixture can escape. When using the RUBERG lamella dumping gutters, fewer modules are required for the suction power of the gutter dust extraction plant, resulting in lower investment and energy costs.

For all design types, the MAC values are far below the required standard.

The exhaust air can be led outside via a silencer and a deflector hood, for example. An air curtain as a recirculation air lock in the access area is another way to use the exhaust air.

Info & downloads

Example tasks:

- Dusting

- Vacuuming

Application areas:

- Cereals

- Coffee & tea

- Oilseeds

Industries & products

Baby food

Baking agents

Building materials

Chemistry

Animal feed

Spices

Plastics

Food

Pharmacy

Ask us!

Would you like a consultation, more information on this machine solution or are you generally looking for a customised overall solution? – Get in touch with us now... Of course, you can also call us directly: Phone number: +49 (0) 5274-98510-0.

We look forward to your inquiry.