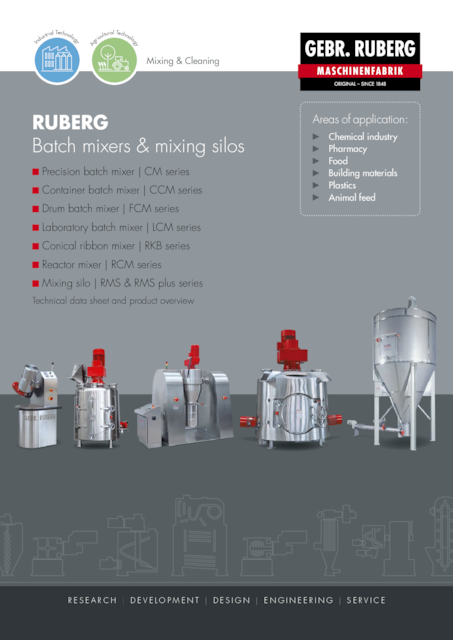

CCM series

The task: compact plant technology with simple logistics in handling containers. Based on the customer requirements, we developed the RUBERG container batch mixers of the series CCM-U (containers docked from below) and CCM-O (containers docked from above).

Products are picked in standard or individual containers of up to approx. 2000 litres (GMP-compliant). The containers are integrated into the mixing process by docking to the swivelling mixing chamber. The mixing variations are equivalent to those of the RUBERG precision batch mixers.

The CCM-U series is suitable for use with containers featuring inlet and outlet cone as well as containers that can be completely opened at the top. The entire unit swivels into working position with the container docked at the bottom and empties the product completely into the mixing chamber. The closed system prevents product emissions in the process. Aspiration and filtration systems are not required. In a very short time, the slow-running mixer produces a completely homogeneous mixture in a way that is very gentle on the product. The unit then swivels back to the home position. The rotating mixer supports the complete emptying of the product back into the container, which is then decoupled and sent for further use.

Info & downloads

Example tasks:

- Mixing

- Batch mixing

- Deagglomeration

- Inerting

- Homogenizing

- Dispersion

- Drying

- Compacting

- CIP

Application areas:

- Baby food

- Baking agents

- Building materials

- Chemistry

- Spices

- Plastics

- Food

- Pharmacy

Industries & products

Animal feed

Cereals

Coffee & tea

Oilseeds

Ask us!

Would you like a consultation, more information on this machine solution or are you generally looking for a customised overall solution? – Get in touch with us now... Of course, you can also call us directly: Phone number: +49 (0) 5274-98510-0.

We look forward to your inquiry.