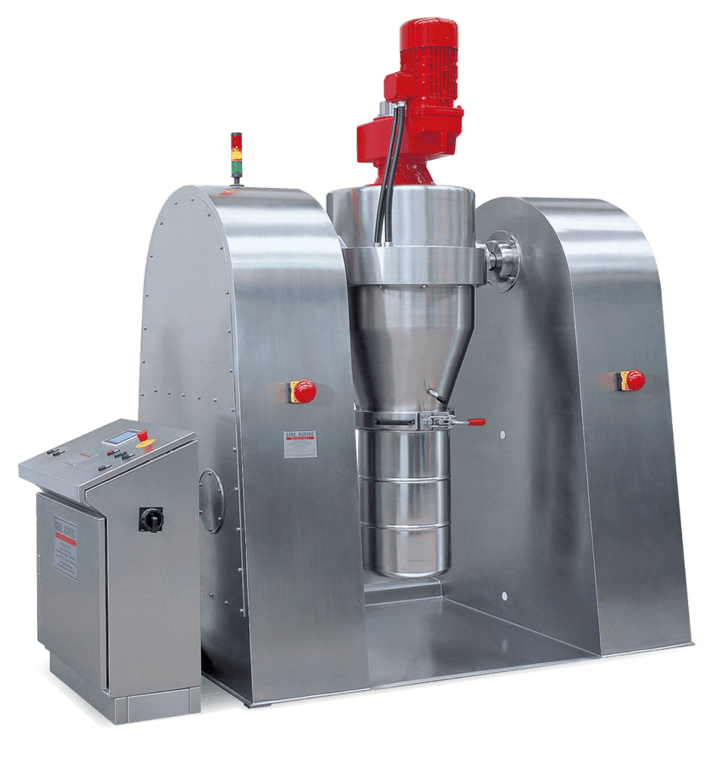

FCM series

Increasing demands and universal application possibilities in daily mixing operations require innovative ideas and specialists who can turn them into reality. From many small and large ideas, we developed the RUBERG drum batch mixer of the FCM series for standard commercial drums.

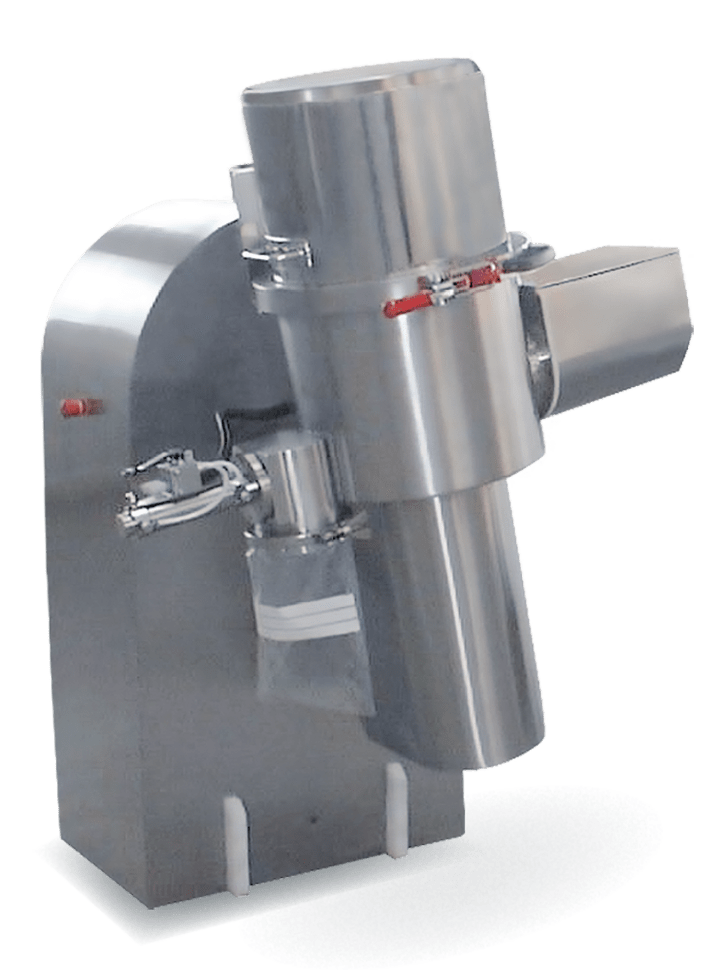

Simple replacement of corresponding adapter pieces allows different drum diameters to be connected. Corresponding adapter pieces are available for special drums and company-specific systems. The batch size can be between 10% and 100% of the mixing chamber volume while maintaining consistent mixing quality. Through the use of cutting rotors, agglomerates can be broken down and various liquids can be added. The design in high-quality stainless or special steels makes the RUBERG drum batch mixer usable in all product areas.

The mixing chamber can be cleaned by swivelling it to a horizontal position and then sweeping or washing it out. Alternatively, you can dock a drum with a cleaning medium and clean by starting a normal mixing cycle.

Info & downloads

Example tasks:

- Mixing

- Batch mixing

- Deagglomeration

- Inerting

- Homogenizing

- Dispersion

- Drying

- Compacting

- CIP

Application areas:

- Baby food

- Baking agents

- Building materials

- Chemistry

- Spices

- Coffee & tea

- Plastics

- Food

- Pharmacy

Industries & products

Animal feed

Cereals

Oilseeds

Ask us!

Would you like a consultation, more information on this machine solution or are you generally looking for a customised overall solution? – Get in touch with us now... Of course, you can also call us directly: Phone number: +49 (0) 5274-98510-0.

We look forward to your inquiry.