BWF, TKF, FBA, SFA series, conveyor systems

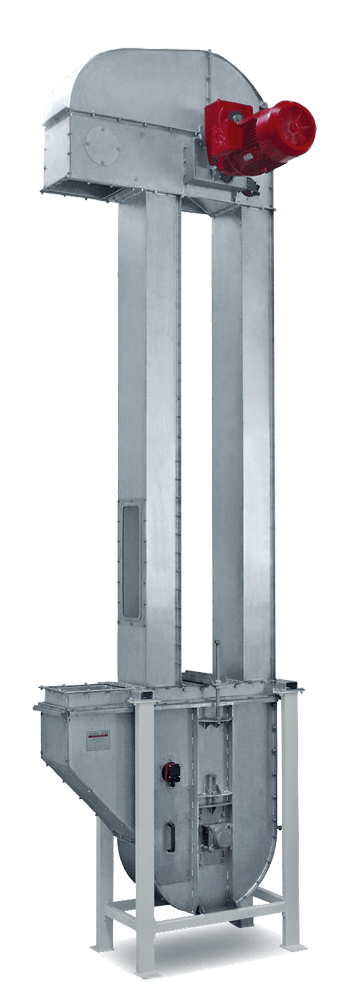

The RUBERG bucket elevator BEG is the ideal solution for vertical transport! Coarse and fine-grained or powdery bulk materials are moved in a gentle, powerful and flexible manner. In single or double design, as a belt or chain bucket elevator with a capacity of 5 to 1 000 m³/h, in normal, stainless or special steel design, special designs also in wood.

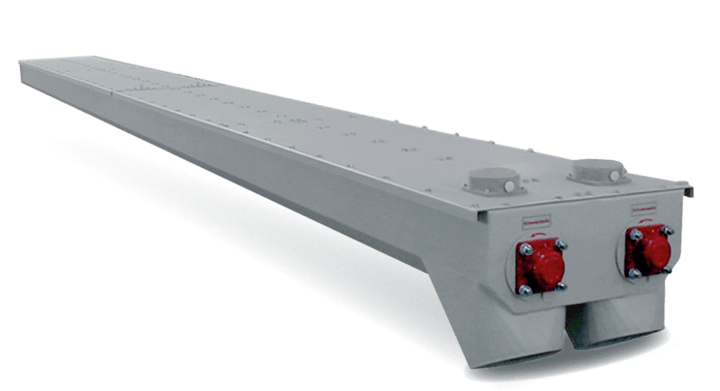

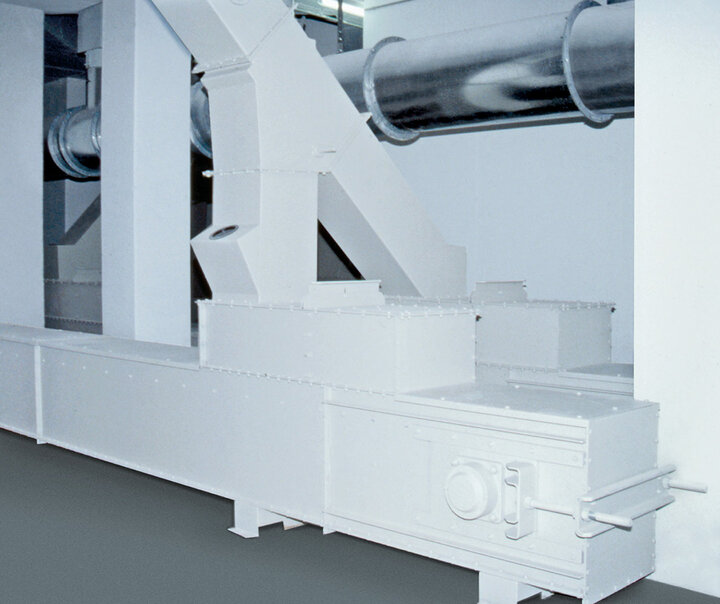

RUBERG trough chain conveyors in flexible design with performance sizes from 5 to 1 000 m³/h. Conveyor link chains pull the bulk material completely dust-free in a closed sheet steel housing. The low chain speed ensures that the material being conveyed is treated particularly gently. Drive station in reinforced steel plate design with hardened sprocket, industrial ball bearing. Drive via hollow shaft gear motor with dampened torque support.

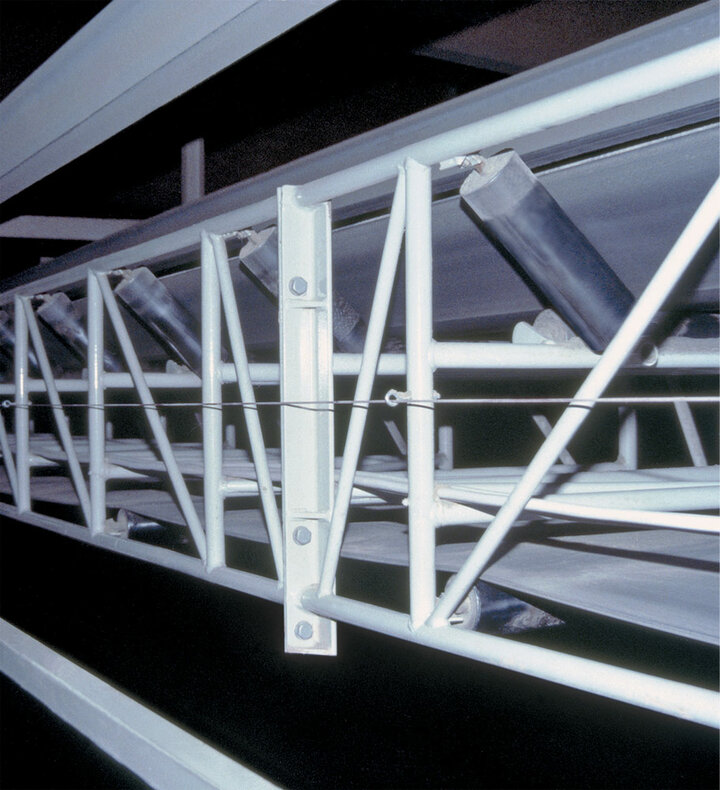

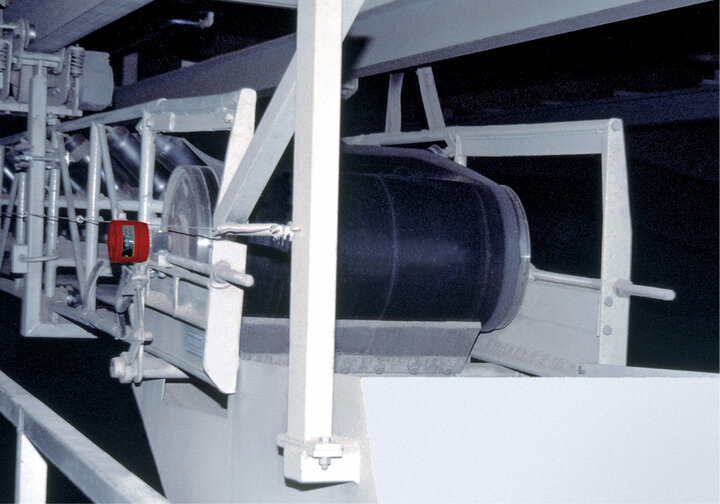

RUBERG conveyor belts as high-performance continuous conveyors for all types of grain, oilseeds, feed, fertilizer and other bulk materials. The intermediate joints with support rollers in two- or three-part trough design and belt return rollers. Carrying rollers with maintenance-free ball bearings. The RUBERG conveyor belts are very suitable for loading and unloading halls. Built in modular design, consisting of the drive and discharge station, intermediate joints and tensioning station.

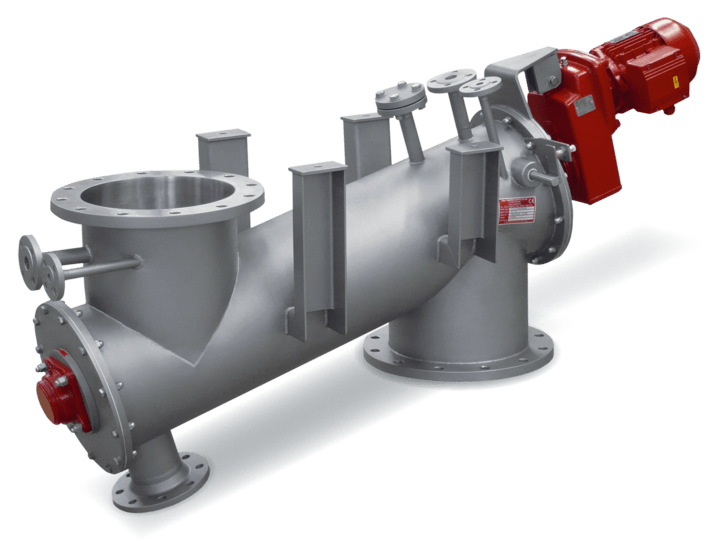

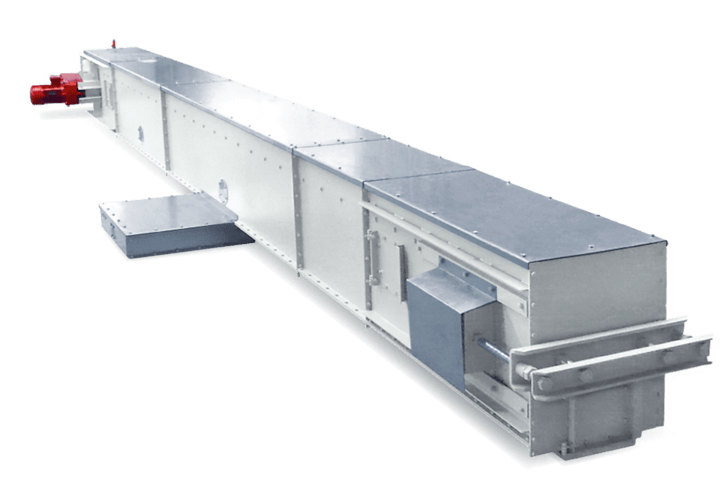

The RUBERG screw conveyor is a versatile conveying element. Thanks to its various designs, it is suitable for all types of bulk materials. Minimum space requirement due to very compact design.Dust-free environment due to low screw speed and closed housing. Screws in standard and stainless steel or special steel, in all diameters and lengths. Depending on the application, RUBERG screw conveyors are used for vertical and horizontal transport.

Info & downloads

Example tasks:

- Conveyors

Application areas:

- Cereals

- Oilseeds

Ask us!

Would you like a consultation, more information on this machine solution or are you generally looking for a customised overall solution? – Get in touch with us now... Of course, you can also call us directly: Phone number: +49 (0) 5274-98510-0.

We look forward to your inquiry.