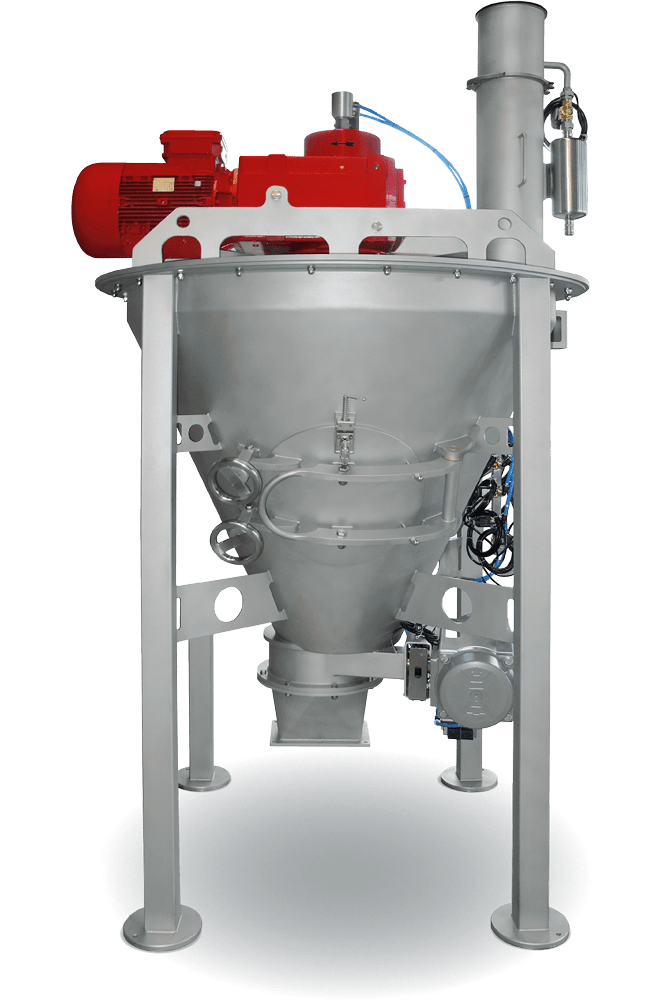

RKB series

The RUBERG conical ribbon mixer is suitable for the production of sophisticated dry material mixtures. Its slowly rotating mixing tools ensure gentle action on the product. The funnel shape of the mixing chamber offers optimum possibilities for attaching a large number of process connections at the top as well as guaranteeing residual emptying at the bottom.

RUBERG conical ribbon mixers of the RKB-ZE and RKB-ZG series extend the performance range of RUBERG batch mixers. Cylindrical mixing chambers with conical bottoms allow batch sizes of 5 – 100% of the usable volume. RUBERG conical ribbon mixers are manufactured in stainless or special steels with high-quality surfaces, according to the product requirements. A large inspection door on the side allows easy cleaning by hand. A sophisticated CIP system is available for fully automatic operation.

Info & downloads

Example tasks:

- Mixing

- Batch mixing

- Deagglomeration

- Inerting

- Homogenizing

- Dispersion

- Drying

- Compacting

- CIP

Application areas:

- Baby food

- Baking agents

- Building materials

- Chemistry

- Animal feed

- Cereals

- Spices

- Coffee & tea

- Plastics

- Food

- Pharmacy

Industries & products

Oilseeds

Ask us!

Would you like a consultation, more information on this machine solution or are you generally looking for a customised overall solution? – Get in touch with us now... Of course, you can also call us directly: Phone number: +49 (0) 5274-98510-0.

We look forward to your inquiry.