KBR series

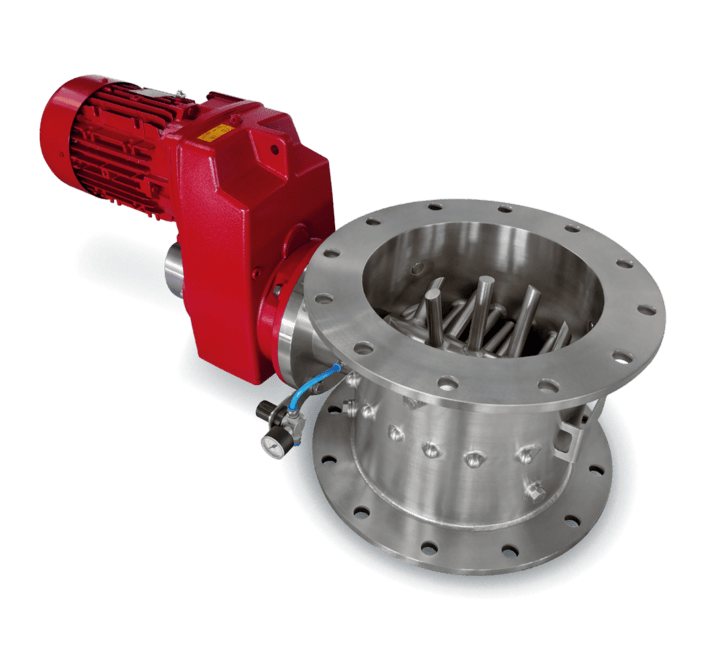

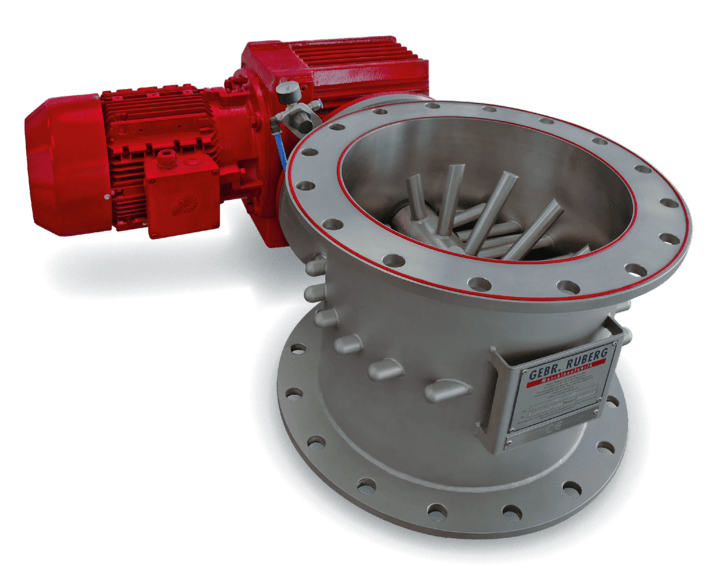

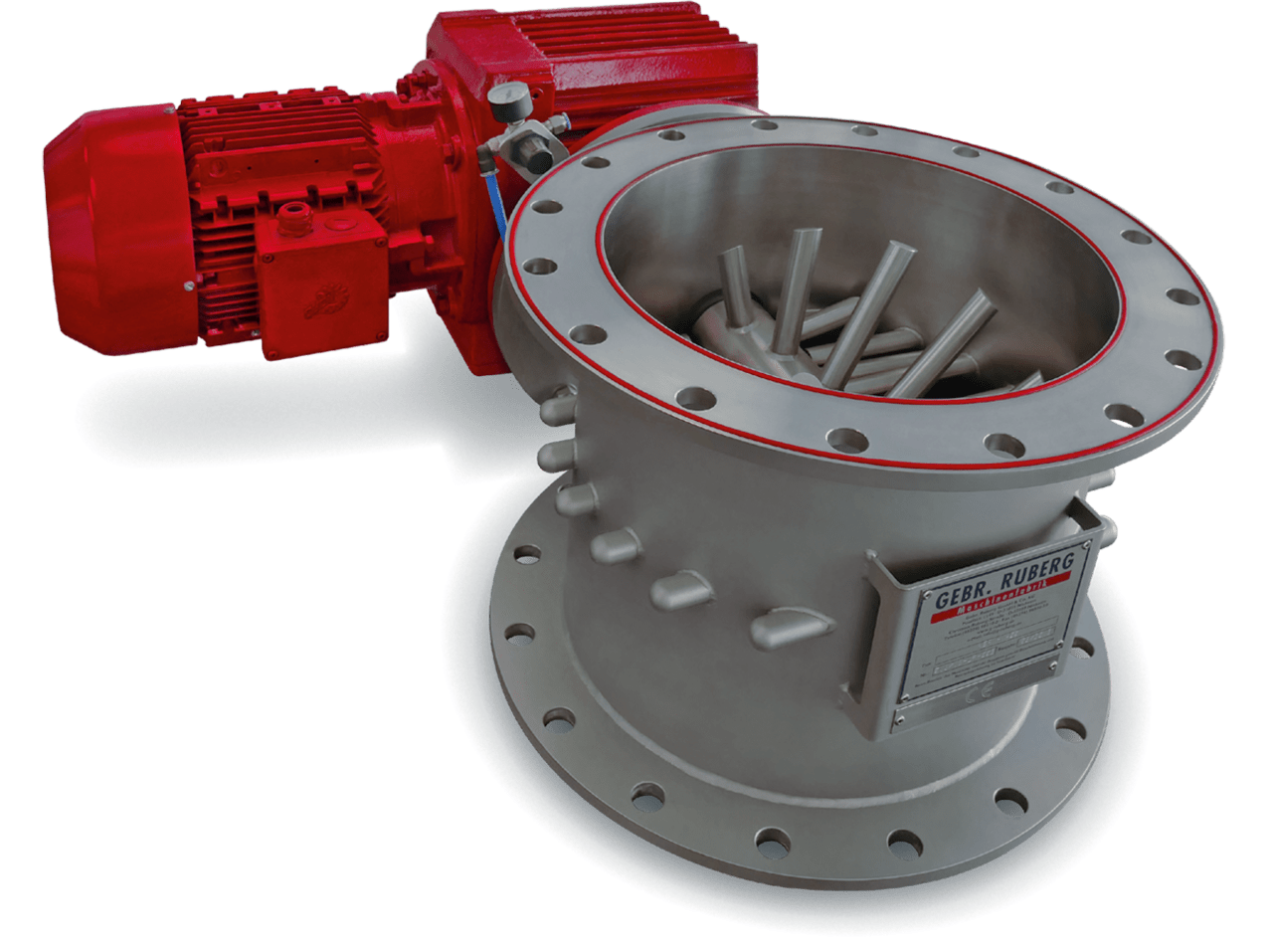

RUBERG lump breakers are used for crushing lumpy bulk materials and raw materials in many industrial sectors. They homogenise the particle sizes and the flow rate of the bulk stream. In doing so, they achieve uniform product transfer from bins, silos, big bags, bag dumps, etc. into conveyors, mixers, process equipment, filling lines, etc.

In high-quality stainless or special steels optionally with wear-resistant coatings or with hygienic surfaces with adequate seals, RUBERG lump breakers find a wide range of applications in the bulk materials, chemical, pharmaceutical and food sectors. Manufactured according to GMP, FDA and ATEX guidelines. The nominal sizes correspond to common standard series. With flat flanges, clamp flanges or straight spigots for sleeves – they can be easily integrated into existing piping, plant components and process apparatus. Heating or cooling jackets for temperature-controlled products, self-closing rinsing nozzles for automatic CIP cleaning and swivel bearings for inspection of the entire unit are examples of additional equipment.

Info & downloads

Example tasks:

- Breaking agglomerates

- Crushing

Application areas:

- Baby food

- Baking agents

- Building materials

- Chemistry

- Animal feed

- Spices

- Food

- Pharmacy

Industries & products

Cereals

Coffee & tea

Plastics

Oilseeds

Ask us!

Would you like a consultation, more information on this machine solution or are you generally looking for a customised overall solution? – Get in touch with us now... Of course, you can also call us directly: Phone number: +49 (0) 5274-98510-0.

We look forward to your inquiry.